Reasons to Choose FeRAM

Introduction

If you are dissatisfied with the specs of your existing memory solutions and feeling the limitations of their performance, FeRAM may be the best alternative.

FeRAM meets various performance requirements for memory at a high level, including fast read and write, low power consumption, and nearly infinite rewrite endurance. It is also non-volatile.

If you are facing barriers to performance with conventional memory solutions, such as system speed, power saving, extending battery life, and frequent data rewrites, then consider using FeRAM.

Five Reasons to Choose FeRAM

1.High read/write cycle endurance

FeRAM guarantees up to 100 trillion rewrites. This is a theoretical endurance of over 3,000 years even when writing at 100 times per second. This means that it can be said that effectively unlimited writing is possible, except for in some applications that require ultra-high-frequency rewriting.

Comparison of upper limits on read/write cycles

| Memory | Maximum number of rewrites | Lifetime at one rewrite per second |

|---|---|---|

| FeRAM | 100 trillion | Approx. 3.17 million years |

| EEPROM | 4 million | Approx. 46 days |

| Flash | 100,000 | Approx. 28 hours |

| Memory | FeRAM |

|---|---|

| Maximum number of rewrites | 100 trillion |

| Lifetime at one rewrite per second | Approx. 3.17 million years |

| Memory | EEPROM |

|---|---|

| Maximum number of rewrites | 4 million |

| Lifetime at one rewrite per second | Approx. 46 days |

| Memory | Flash |

|---|---|

| Maximum number of rewrites | 100,000 |

| Lifetime at one rewrite per second | Approx. 28 hours |

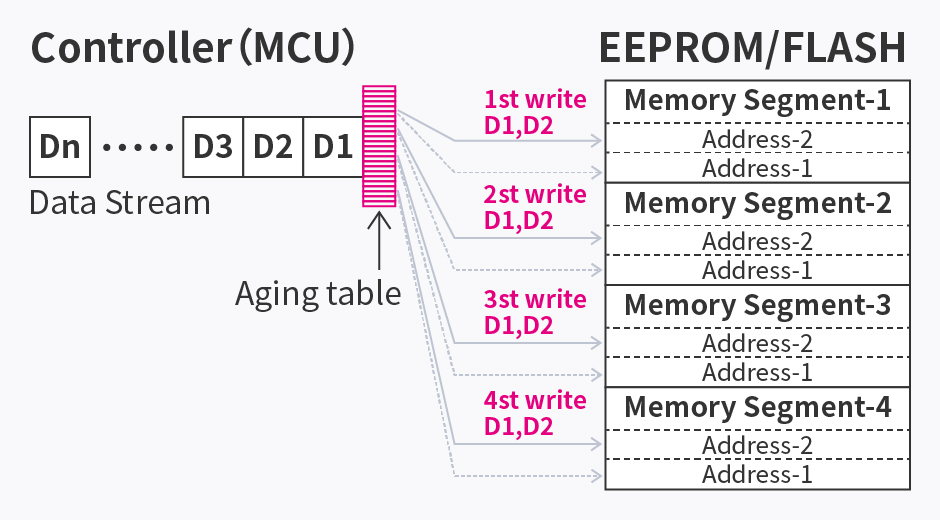

No wear leveling required

No wear leveling required

Wear leveling(*) is common in applications that exceed the upper limit of rewrite endurance tolerances for EEPROM and flash memory.

* A method of distributing rewrites across multiple memory units.

- Increase in software complexity

- Increase in validation hours as a result

- Increased risk of market bug leaks

- Since the software is simplified, there are no disadvantages as with wear leveling

- Reduction in development work hours

- Can also be expected to reduce market bugs and improve customer satisfaction

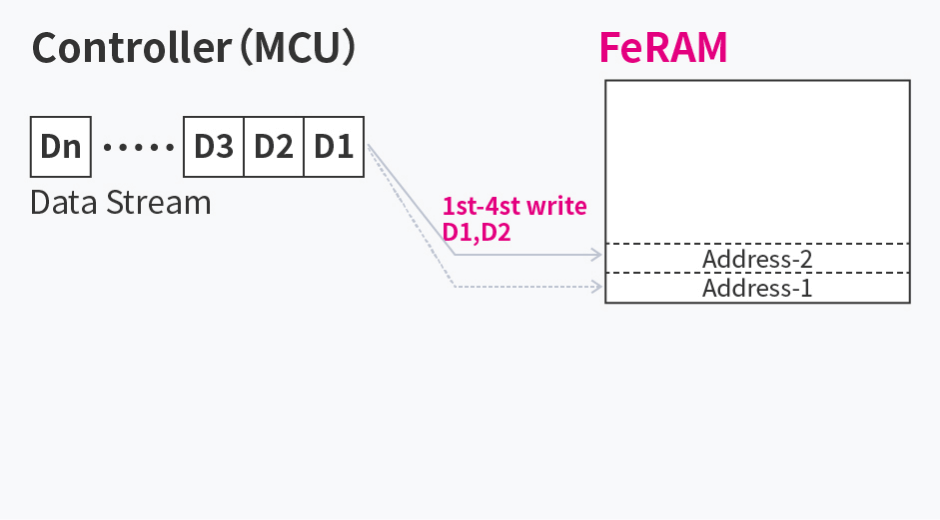

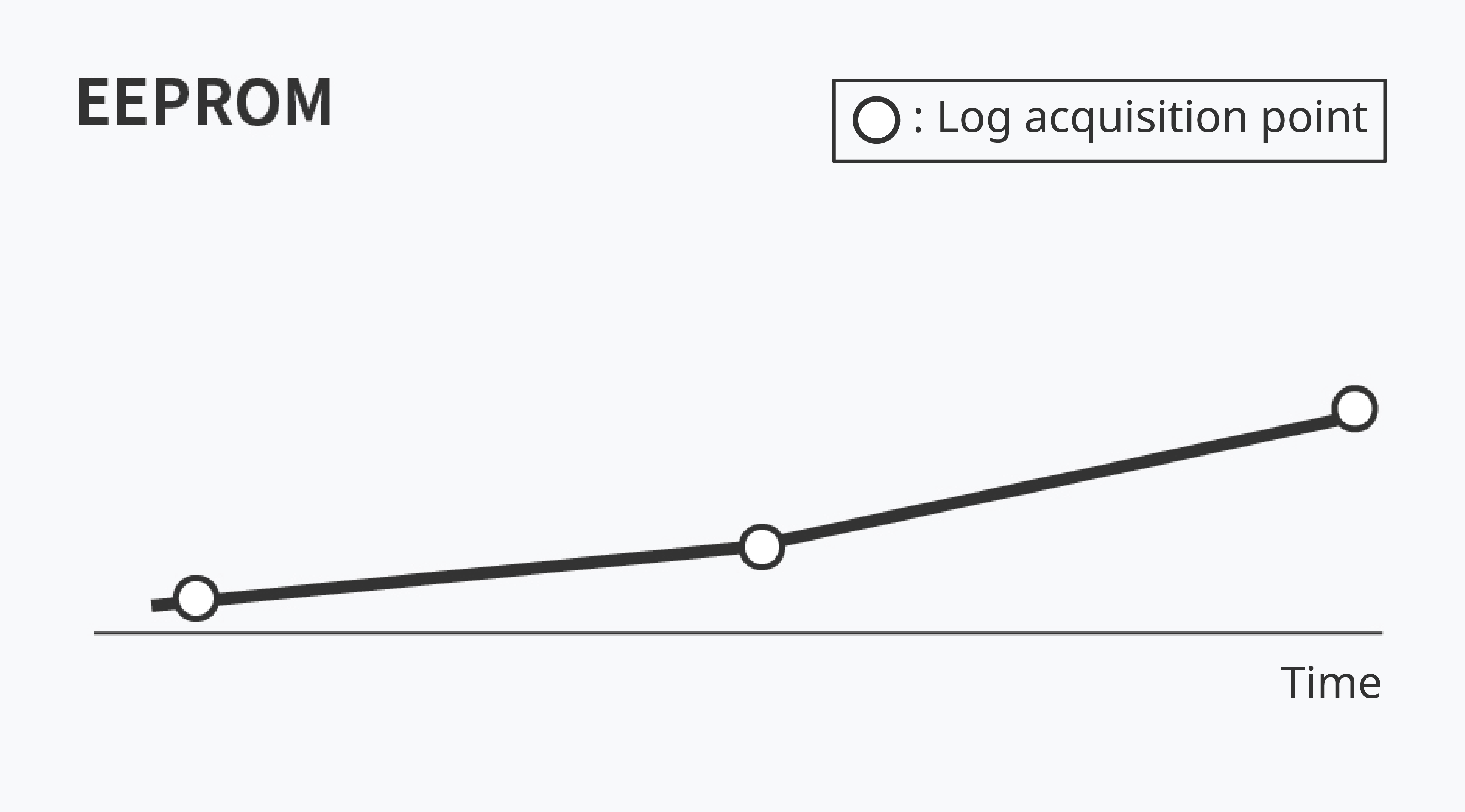

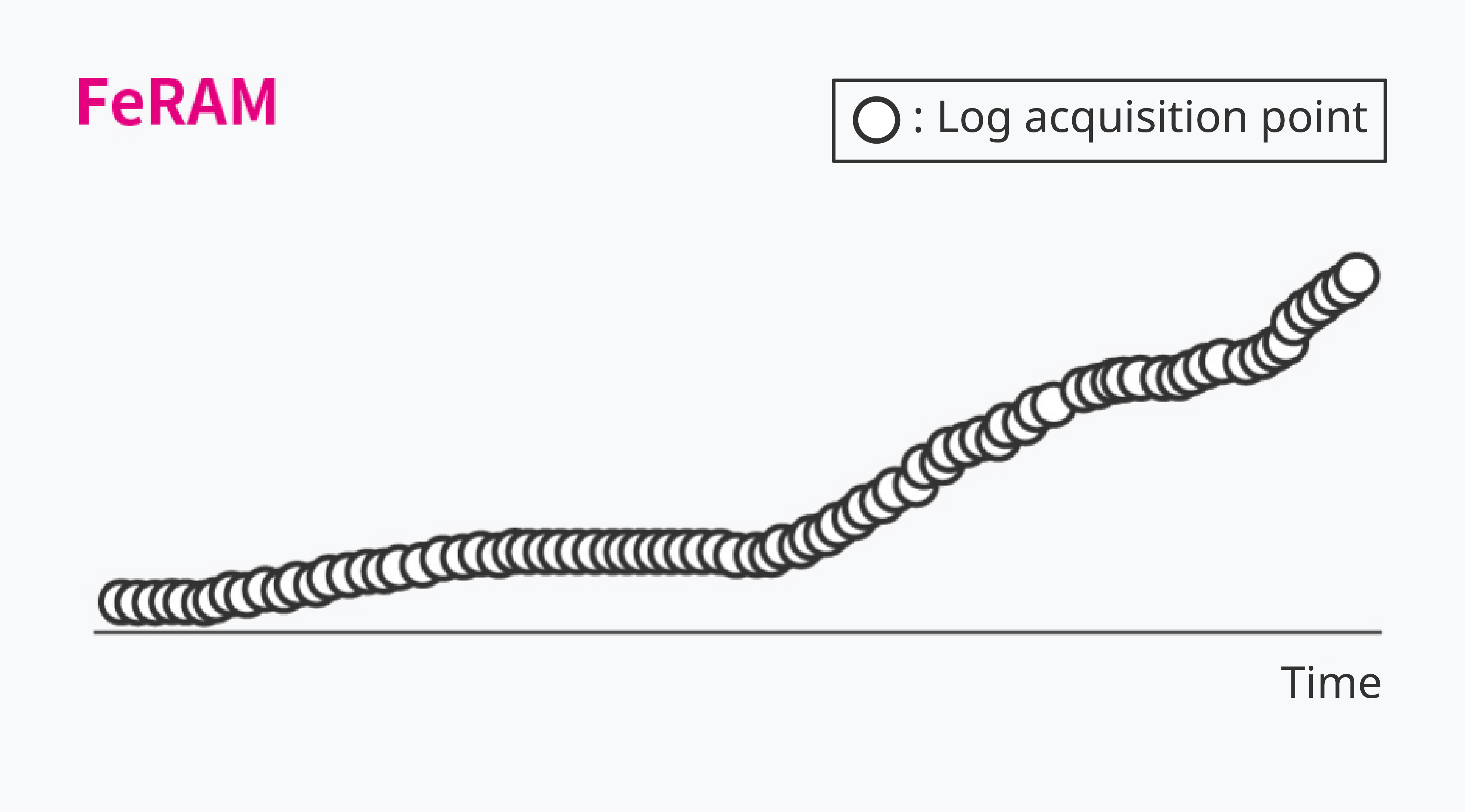

High-frequency log acquisition possible

High-frequency log acquisition possible

The high rewrite endurance of FeRAM makes it possible to collect data with a high degree of frequency and accuracy. By knowing the complex data curves that could not be confirmed previously, we can see the true movement of data.

- When writing over a period of 10 years, EEPROM is limited to 11 write operations per hour, or around 270 write operations per day

- There is a possibility that you may not be getting the data you require

- Higher frequency data acquisition requires measures such as wear leveling, which leads to higher complexity in software

- FeRAM can be rewritten up to 300,000 times per second (over 20 billion times per day)

- Data changes can be recorded in small increments, making it possible to accurately acquire real data

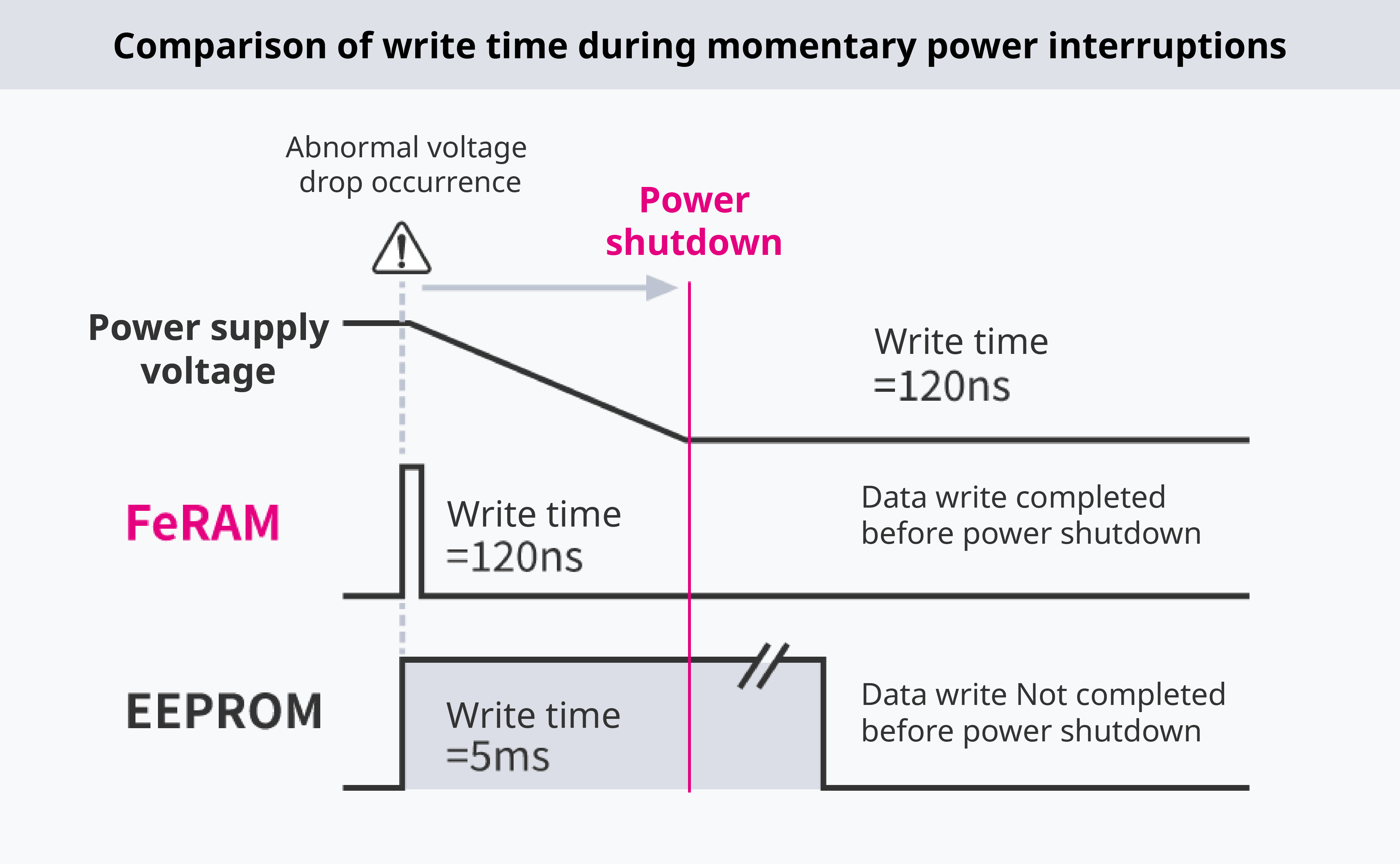

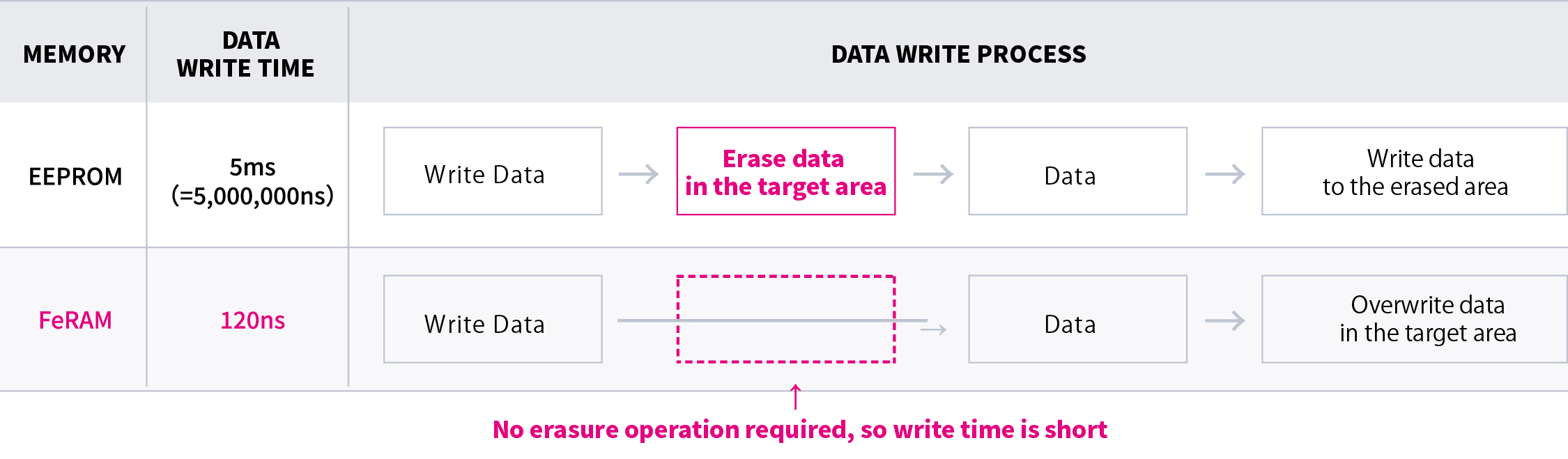

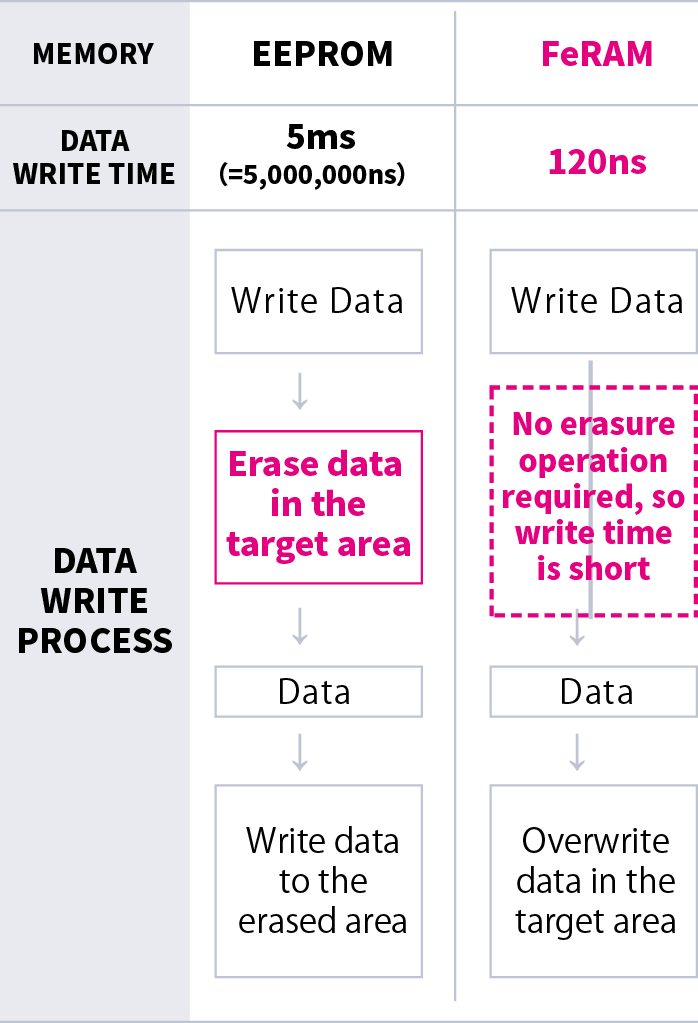

2.High-speed writing

FeRAM requires around 120ns per write operation. This is over 40,000 times faster than EEPROM.

Data can be reliably recorded even in the event of a power outage or momentary interruption

Data can be reliably recorded even in the event of a power outage or momentary interruption

Wear leveling is common for applications that exceed the rewrite tolerance limits of EEPROM and FLASH.

*Wear leveling is a method of distributing rewrites across multiple memories.

- Since the write time is on the order of milliseconds, there is a high possibility that the data being written will be lost if the power supply is interrupted during a write or erase operation

- With FeRAM, write operations take 120ns, so data writing is completed before power loss

- Logs can be taken reliably even in the event of a sudden power outage

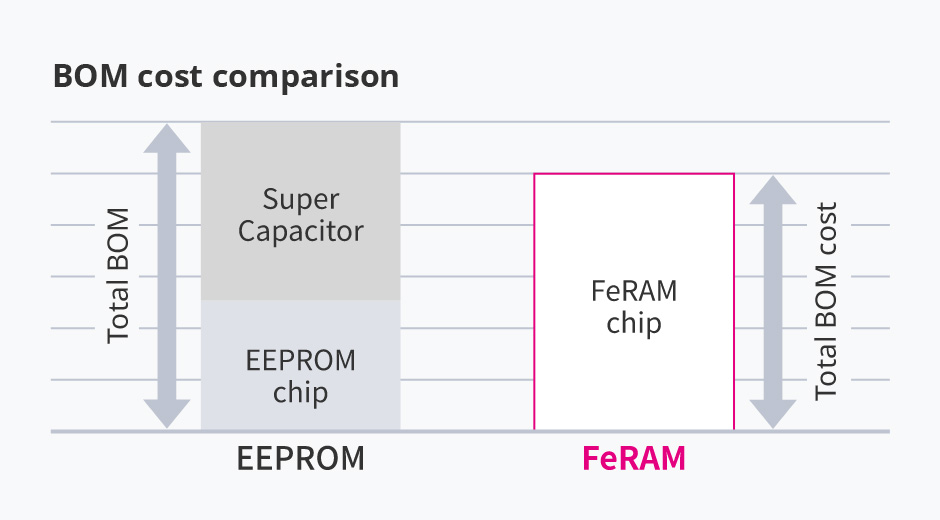

Cost reduction by reduction of peripheral parts (BOM cost reduction)

Cost reduction by reduction of peripheral parts (BOM cost reduction)

- Recording data just before a momentary power outage requires a supercapacitor or battery

- Even if memory alone is inexpensive, BOM costs will increase due to additional parts

- No supercapacitors or batteries required

- Total BOM costs can be reduced

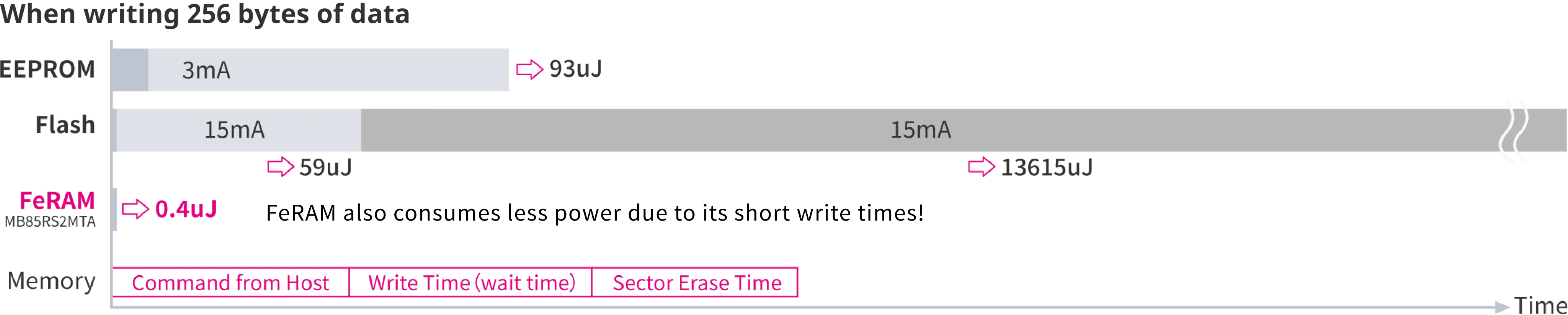

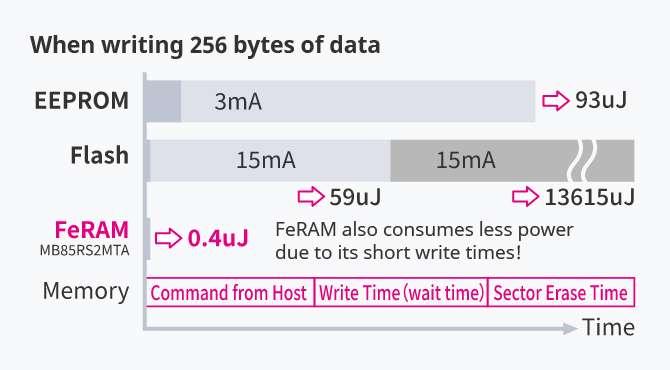

3.Low power consumption

FeRAM achieves low power consumption compared to other types of memory for the following two reasons.

- Short write times and low power consumption during write operations

- Non-volatile memory eliminates the need for current for data retention

Low write energy enables reduced power consumption

Low write energy enables reduced power consumption

- Large amount of power required for write operations, affects battery life

- The write energy of FeRAM is 1/100th that of EEPROM and 1/20,000th that of flash memory

- Enables significantly longer battery life when used in write-intensive applications

- Contributes to reducing environmental impact

4.Simple write operation

FeRAM achieves simple write operation for the following two reasons.

- Memory can be overwritten directly, eliminating the need for pre-erasure operations

- There is no concept of pages or sectors, meaning that entire areas can be written consecutively

No erase operation is required, enabling writing without concern for pages or sectors

No erase operation is required, enabling writing without concern for pages or sectors

- With EEPROM memory, it is necessary to divide write operations according to page size limits

- Flash memory requires sector-by-sector erase operations

- Increase in software complexity as a result

- With FeRAM, there is no need for erase operations, only write operations

- Software is simple as a result

- Reduction in development and bug validation work hours, etc.

5.Easy replacement of existing memory

Drop-in replacement of EEPROM or SRAM possible

Drop-in replacement of EEPROM or SRAM possible

- Replacing existing memory seems likely to take a lot of development work hours...

- We want to reuse existing controllers and boards

- We also want to minimize changes to software

- We offer both serial (SPI/I2C) and parallel interface products

- A wide lineup of capacities, voltage ratings, and packages are also available

- Easy to replace existing memory

| Interface | I2C | SPI | Parallel |

|---|---|---|---|

| Memory density | 4K〜1Mbit | 16K〜8Mbit | 256K〜8Mbit |

| Power supply voltage |

|

|

1.8〜3.6V |

| Operating temp. |

|

|

|

| Package | SOP,SON,DFN | SOP,SON,DFN,BGA,WL-CSP | TSOP,FBGA |

| Interface | I2C |

|---|---|

| Memory density | 4K〜1Mbit |

| Power supply voltage |

|

| Operating temp. |

|

| Package | SOP,SON,DFN |

| Interface | SPI |

|---|---|

| Memory density | 16K〜8Mbit |

| Power supply voltage |

|

| Operating temp. |

|

| Package | SOP,SON,DFN,BGA,WL-CSP |

| Interface | Parallel |

|---|---|

| Memory density | 256K〜8Mbit |

| Power supply voltage |

|

| Operating temp. |

|

| Package | TSOP,FBGA |