Battery Energy Storage Systems (BESS) increasingly rely on advanced memory solutions like FeRAM for high-speed logging and reliability. This article explores what BESS is, how FeRAM improves system performance over other non-volatile memories, and real use cases in PCS/BMS applications.

FeRAM in BESS: Overview & Technical Guide

FeRAM’s high-speed writing and exceptional rewrite endurance allows it to play a critical role in the Power Conversion System and the Battery Management System of Battery Energy Storage Systems, also called BESS. It enables rapid recovery from power disruptions and simplifies root cause analysis, reducing system downtime, making RAMXEED’s FeRAM a great fit for BESS.

What is a Battery Energy Storage System (BESS)?

Mechanism of BESS

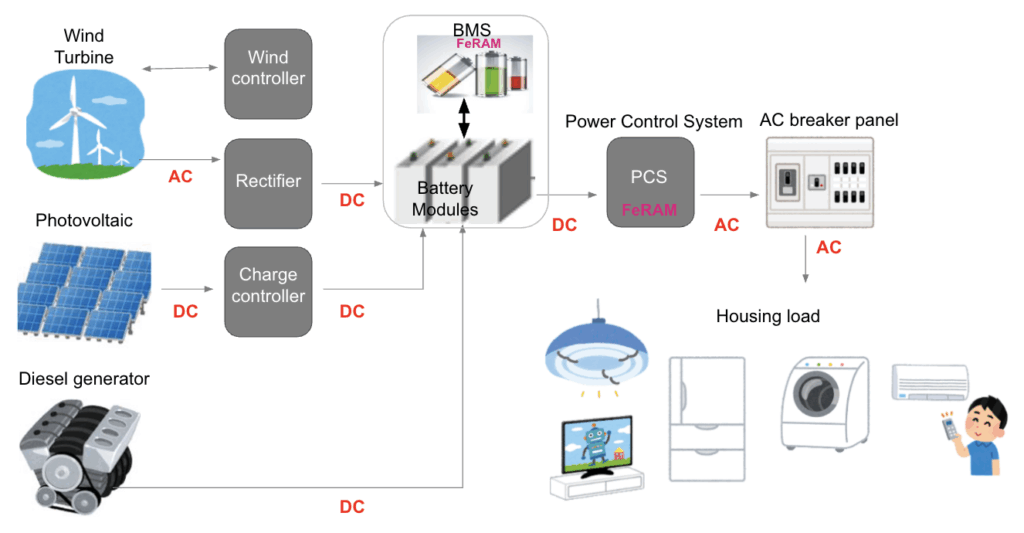

A utility-scale Battery Energy Storage System stores electrical energy in rechargeable batteries and releases it back to the power grid when needed. This process ensures reliable electricity supply and supports critical grid services such as frequency regulation and peak load management.

Without energy storage, electricity must be generated and consumed simultaneously, which limits flexibility. BESS technology enables strategic energy storage and discharge at the most critical times and locations, improving grid stability, integrating renewable energy sources, and reducing operational costs. BESS and its components play a big part in increasing Sustainability.

BESS

BESS can store energy from both renewable and non-renewable sources. Stand-alone batteries are charged from the power grid and are not physically co-located with solar power plants. These independent systems provide services at critical transmission and distribution levels in response to the overall state of the power system.

BMS

The Battery Management System acts as the central intelligence of a battery rack. Its primary role is to continuously monitor key parameters such as voltage, current, temperature, and state of charge for each battery module. By doing so, it ensures optimal performance and prevents conditions that could lead to overheating, overcharging, or deep discharge, all of which can damage the battery or pose safety risks. Additionally, the BMS manages cell balancing, communicates with higher-level controllers, and provides diagnostic data for predictive maintenance. In short, it safeguards the battery system while maximizing efficiency and lifespan, leading to a more sustainable path.

Main Components of a BESS

A BESS consists of a Power Conversion System, battery modules with built-in BMS, battery racks, and battery enclosures.

Why FeRAM Matters in BESS?

BMS must continuously record, in real time (every 0.1 to 1 second), the temperature, voltage, current, charge/discharge status, and historical data of battery cells to ensure all cells remain balanced.

The PCS must continuously record real-time log information such as current, voltage, frequency, and faults, every 2 seconds for 24 hours, including the critical two seconds before a fault occurs. This facilitates troubleshooting and debugging during power system failures, enabling rapid restoration of operation and maintaining these parameters at normal levels.

FeRAM, with its high-speed write capability and exceptional durability, is considered the most ideal memory for BESS.

The benefits of using FeRAM in BESS are as follows:

- System restart from the immediate state before failure even in the case of unexpected power failure occurrence.

- Easier troubleshooting, and system minimized downtime allowed by the FeRAM recorded data prior failure.

- Possible implementation of a more compact PCB design without supercapacitors compared with EEPROM and flash memory which require longer write times, and to compensate for this during power interruptions, large supercapacitors.

- Sustainability Increase related to FeRAM’s ultra-low consumption.

Key Use Cases in PCS & BMS

In PCS, FeRAM enables system restart by accurately monitoring what happened immediately before any incident or failure.

For BMS, there is a need for constant logging for battery reuse evaluation. Today’s EV batteries are being developed and regulated not only to extend their life, but also to reduce their environmental impact through reuse. The use of FeRAM, which can withstand 10 trillion rewrites, enables constant logging while the battery is in use.

➤Learn more about FeRAM for BMS

FeRAM vs Other Non-Volatile Memories

Since FeRAM guarantees over one trillion rewrite cycles, even with data logging every 100 milliseconds, it is calculated to withstand rewriting for more than 100 years as specified in the table below, showing FeRAM vs. Flash Memory and EEPROM.

| Memory type | Part number | Rewrite endurance | Lifespan | Logging Support | Use in BESS |

| FeRAM | MB85RS1MT | Very High | Over 100 years | Yes | Ideal |

| EEPROM | M95M01 | Low | 27 hours | Limited | Not Ideal |

| NOR FLASH | W20Q10RL | Medium | 2.7 hours | Limited | Not Ideal |

Recommended Products

PCS

MS85R4M2TA

Interface: Parallel

Capacity: 4Mbit

Operating power supply voltage: 1.8V ~ 3.6V

Operating Speed: 120ns

Operating Temperature: -40°C ~ 85°C

Package: TSOP44

MB85RS2MTA

Interface: SPI

Capacity: 2Mbit

Operating power supply voltage: 1.7V ~ 3.6V

Operating Frequency: 40MHz

Operating Temperature: -40°C ~ 85°C

Package: SOP8

MB85RS1MT

Interface: SPI

Memory Density:1Mbit

Operating power supply voltage: 1.8V ~ 3.6V

Operating Frequency: 30MHz

Operating Temperature: -40°C ~ 85°C

Package: SOP8

MB85RS258B

Interface: SPI

Capacity: 256Kbit

Operating power supply voltage: 2.7V ~ 3.6V

Operating Frequency: 33MHz

Operating Temperature: -40°C ~ 85°C

Package: SOP8

BMS

MB85RS2MTA

Interface: SPI

Capacity: 2Mbit

Operating power supply voltage: 1.7V ~ 3.6V

Operating Frequency: 40MHz

Operating Temperature: -40°C ~ 85°C

Package: SOP8

MB85RC512T

Interface: I2C

Capacity: 512Kbit

Operating power supply voltage: 1.7V ~ 3.6V

Operating Frequency: 3.4MHz

Operating Temperature: -40°C ~ 85°C

Package: SOP8